LEGO Storage System

Since 2019, I have been running an online store for LEGO parts on BrickLink. Customers can order individual parts from several thousand unique references. Good stock organization is therefore critical. At first, I used a commercial solution, which helped me get started but eventually showed its limitations. I then undertook to create a completely custom storage solution.

Let’s start by presenting the commercial solution.

The pros and cons of Papi Max StackX Drawers

Papi Max StackX Drawers is a product specifically designed for LEGO enthusiasts, promising high storage density. The system consists of individual modules composed of an external case in which a drawer slides. The cases are available in white or black and can be stacked and assembled together. The drawers are transparent and equipped with a handle at the front. Up to four dividers can be added in width and two in length to form up to 15 compartments.

A detailed review of the product is available on the Brick Architect website

The pros 👍

- Sold as individual elements, allowing to form an overall structure of any size and shape

- Adjustable internal layout

- Possibility to completely remove a drawer to take it to the work area

- Drawers can come out almost completely allowing easy access to the entire surface

The cons 👎

- Impossible to extract an individual compartment to bring it to the work area or empty its contents (this makes moving pieces from one compartment to another very tedious)

- Difficult to reconfigure dividers when compartments are occupied

- Dividers are not locked and can lift up and let pieces leak into neighboring compartments

- The drawer easily gets stuck or blocked if not handled carefully

- The transparent plastic of the drawers is subject to yellowing in sunlight

- High price

Eventually, the removable divider system was appealing on paper but impractical in use. Added to that, the low build quality and high price were prohibitive to continue with this solution.

LASER cutting and modular boxes

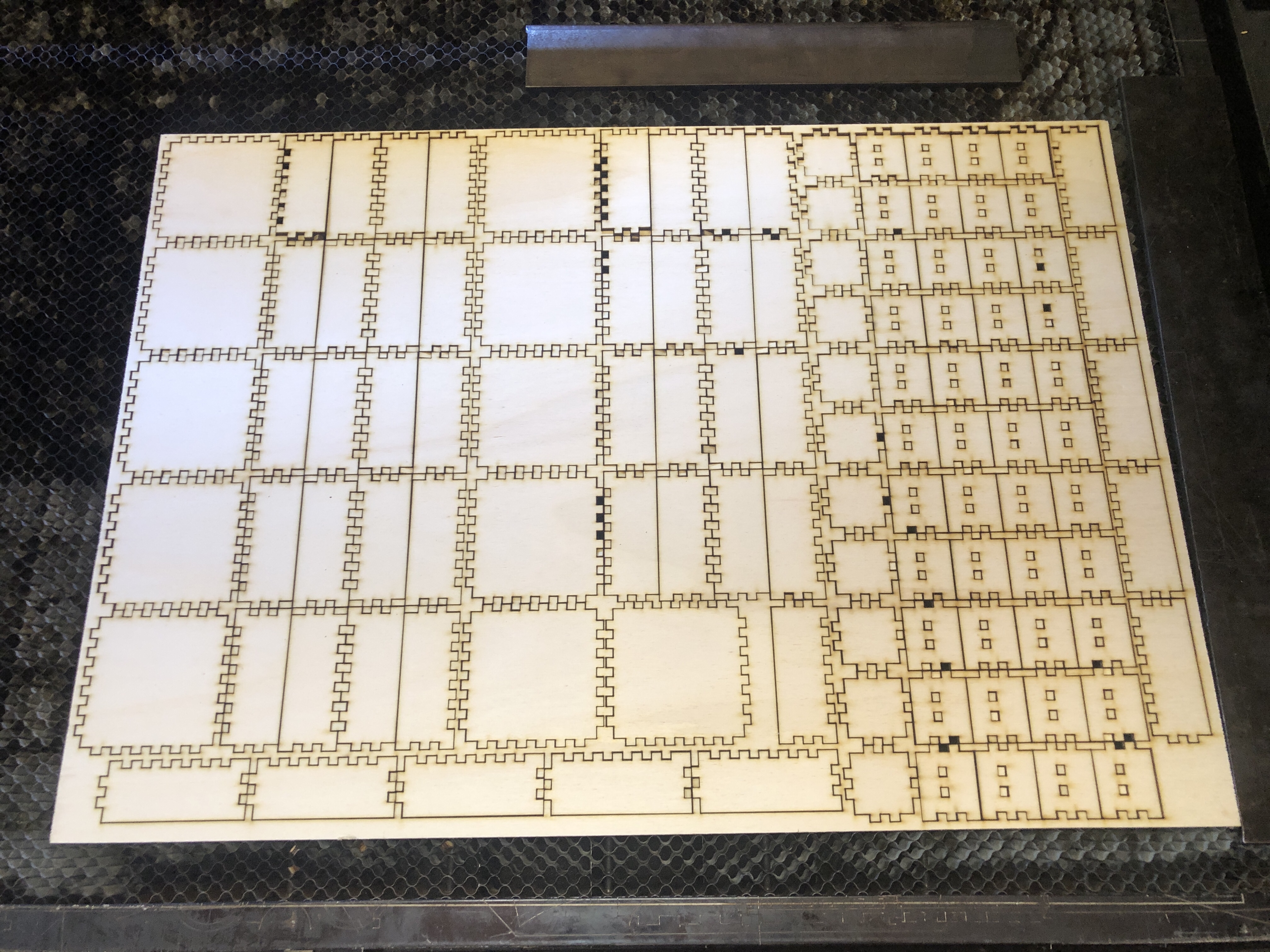

In 2021, I had the opportunity to learn LASER cutting in a makerspace near my home. After a training session, I started experimenting with this machine, and I quickly grasped its potential for making boxes that could serve as the basis for a custom storage solution, where you can carry, move, and arrange compartments in drawers at will.

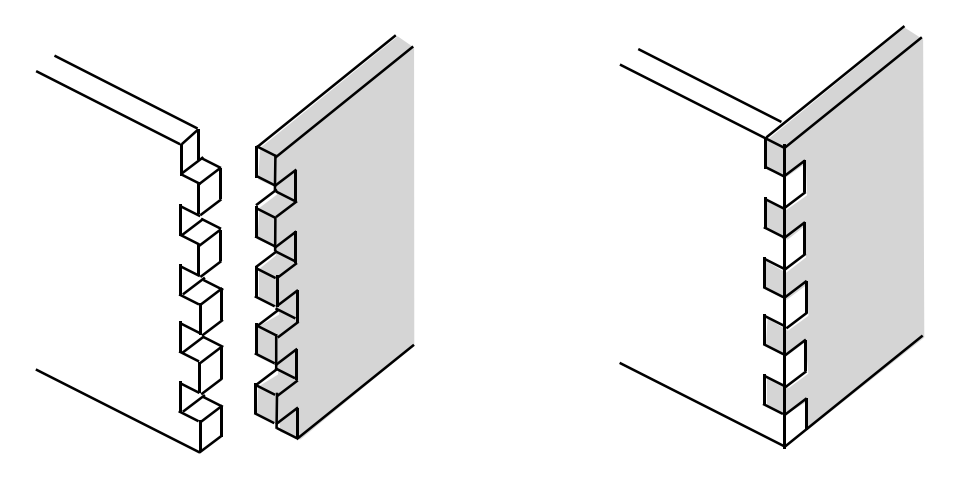

After quickly exploring different box assembly and construction techniques, I settled on a tight notch assembly. By adjusting the relative size of the notches well, it’s possible to assemble the pieces with a mallet and it holds perfectly without glue. A simple solution as I like them.

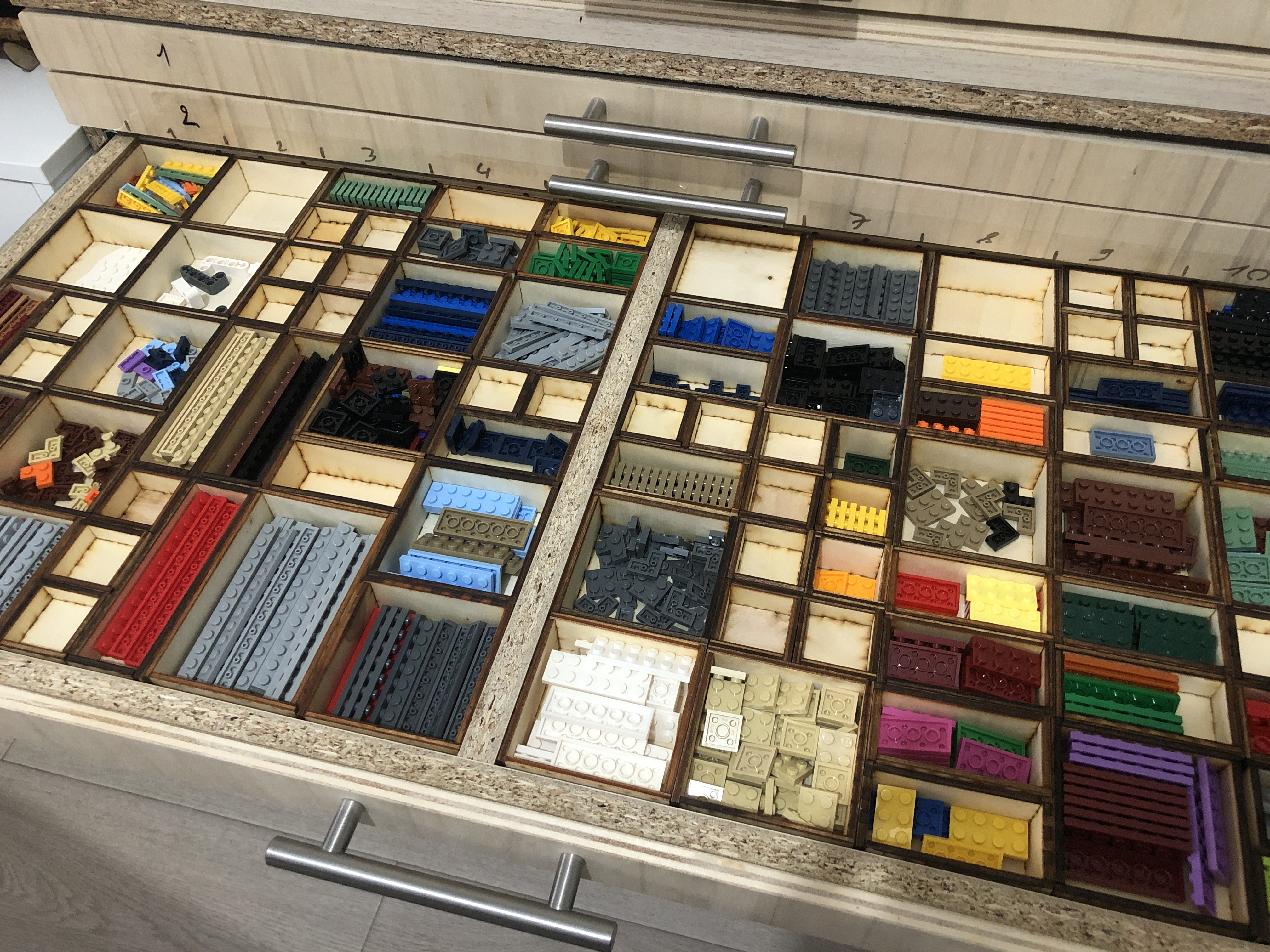

The idea then was to make a system of modular boxes that can be arranged freely in large drawers. This system allows easy carrying, moving, and emptying of compartments.

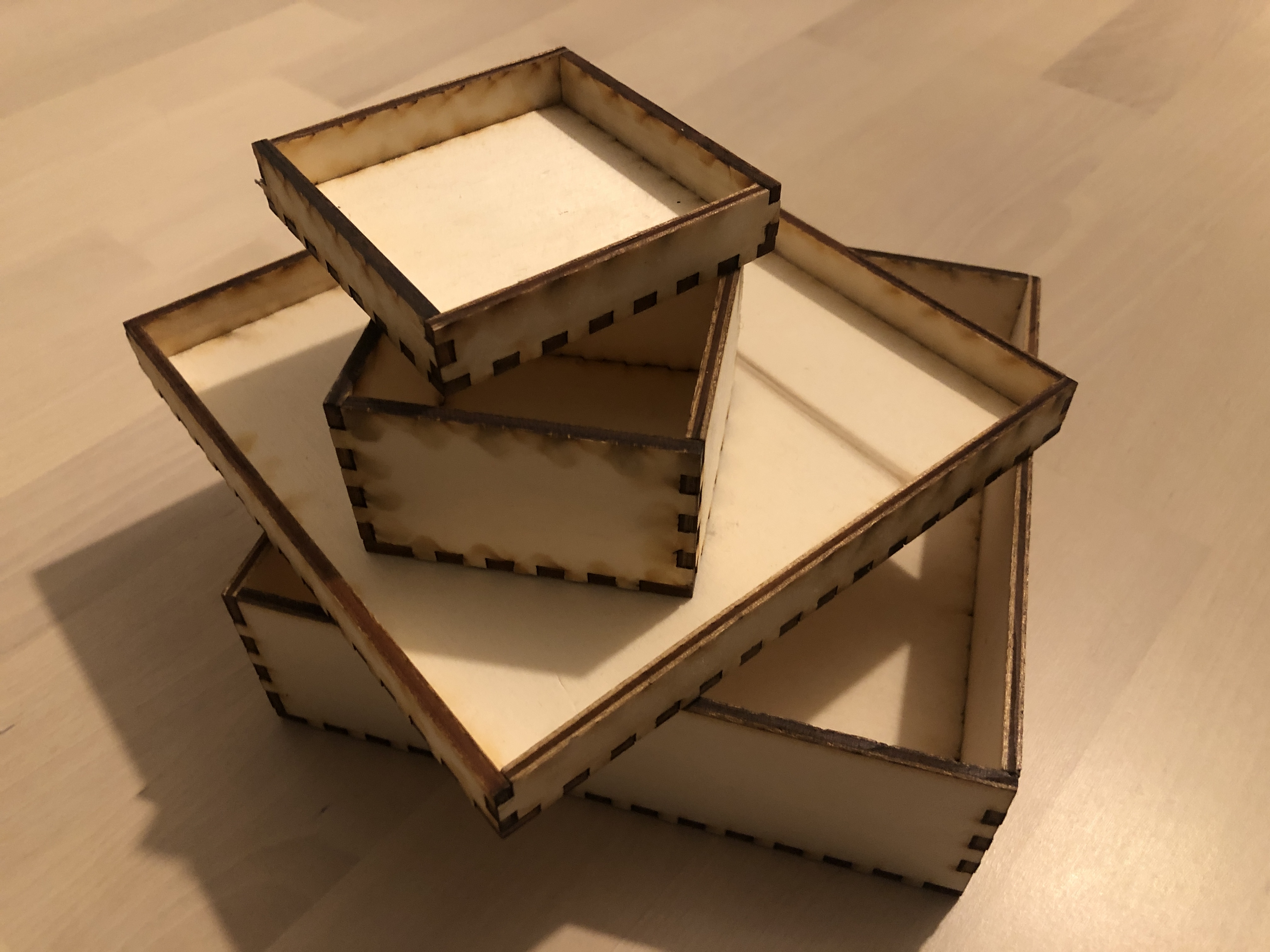

I based the size of the first boxes on the size of the previous compartments, resulting in a square box of 75mm per side. A box with these dimensions can accommodate a LEGO piece 8 units long with just enough margin. For the height, I wanted to respect the LEGO brick ratio, considering that my box was equivalent to a 2x2 brick. LEGO experts know that the height of a 2x2 brick equals 3/5th of its width. For a 75mm side box, we thus get a height of 75*3/5 = 45mm. I found this too high, so I removed one third (which in the LEGO world corresponds to going from brick height to two plate height) which gives 30mm. I find this to be the perfect ratio.

From there, assuming my base box is 2x2 units wide and 2 plates high, I experimented with all kinds of variants in 1x1, 1x2, 2x3, 2x4, 3x3, etc. in versions of 1, 2, 3, or 4 plates high.

I quickly realized that large size and low height models are useful as trays for containing pieces during construction, for example. I made bigger ones, which I still commonly use today.

Some drawers to store the boxes

When I started having a certain number of loose boxes, the need for a higher level of storage became apparent. I started experimenting with a module system similar to Papi Max, using the same LASER cutting manufacturing technique as for the boxes. It wasn’t perfect but it was very encouraging and motivated me to continue.

For the next step, I wanted a quality feel when opening and closing the drawers. This was important to me. I wanted my drawers to give an impression of solidity and quality, with smooth opening and closing, without tilting as the drawer opens, and without fear of dislodging the drawer if opened too quickly. I also wanted the drawers to be able to open to full depth to allow access even to boxes at the back.

After some research, I found a model of full extension slides on Amazon, available in several lengths, that seemed to meet my quality requirements.

Full extension slides found on Amazon

After some experimentation with the slides, I built a first furniture prototype with 10mm poplar plywood. I cut the pieces with a jigsaw but the result was very mediocre. Nothing was really straight, and the opening/closing of drawers wasn’t smooth and open drawers would collide.

The makerspace that houses the LASER cutter also has a woodworking shop. After completing the necessary training, I undertook a second prototype, this time using the table saw. The result was significantly better.

Real large furniture

I had a prototype that I really liked and I was now very eager to continue by making larger furniture. I started by making a piece twice as wide based on the same model as the prototype. Apart from the drawer bottoms sagging under the load, it worked well and motivated me to continue.

For the next piece of furniture, I went big right away: 15 drawers + 1 double height drawer for bigger pieces. Except for the fronts, everything was made from reclaimed materials. Compared to the previous model, I added a partition that cuts the drawer in two to support the bottom.

Conclusion and next steps

I now have a total of 5 pieces of furniture of different capacities that I use daily to store my LEGO pieces for my online store. The modular box system allows carrying, moving, and arranging compartments in drawers at will. Drawer opening is smooth, effortless, and gives a quality feel that I really like.

I always need more storage space, and I plan to make more furniture, always seeking to improve the design. I’d like to succeed in better aligning the drawers with each other. I’d also like to find a solution to the fact that the slides don’t allow the drawer to extend beyond its depth, which still makes access to the back boxes difficult, especially when there’s the handle of the drawer above just overhead.

For the next pieces of furniture, I’d like to try adding a large illustration that spans across the drawer fronts.

I’m also thinking about making modules to insert into IKEA Kallax shelves.

I use generative AI to write and/or translate the content featured on this website. AI serves only as a tool for productivity and inspiration, I make sure that the final texts always reflect my personal voice and style.